SIPOC : Your SME’s path to process excellence

Small and medium-sized enterprises (SMEs) often find themselves wrestling with the challenge of continuous improvement.

The popular choice is Lean methodology, with its promise of waste elimination and efficiency gains.

But, let’s face it, Lean can be like navigating a labyrinth for many SMEs, consuming precious time and not always delivering the expected results.

So, what’s the alternative that’s gaining momentum?

Enter SIPOC, a simpler and more agile approach that promises to unravel the complexities, boost efficiency, and pad the bottom line for SMEs.

Why SIPOC Over Lean?

Lean is a powerhouse when it comes to streamlining processes, but it’s not a one-size-fits-all solution.

SMEs often operate with limited resources and tight schedules, making the complexity of Lean a less practical choice.

That’s where SIPOC shines, as it’s a more flexible and inclusive Six-Sigma approach that can be embraced by teams from various departments.

SIPOC: A Power-Packed tool

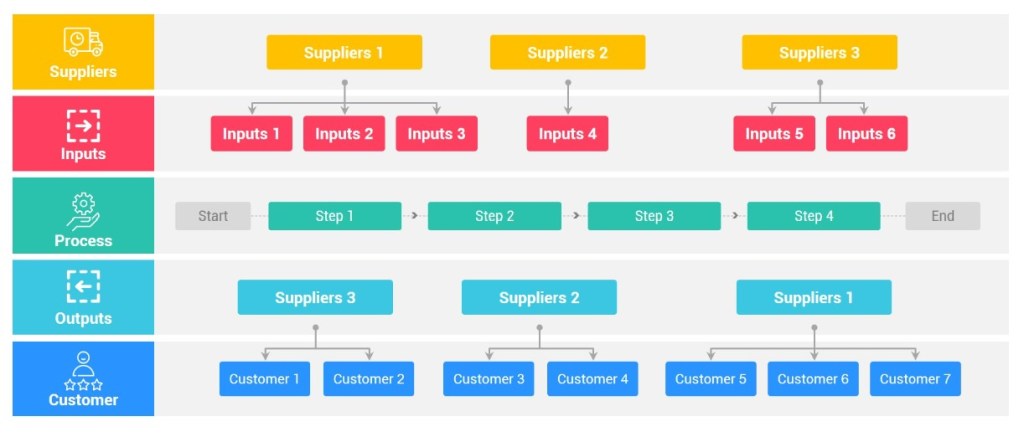

SIPOC stands for Suppliers, Inputs, Process, Outputs, and Clients. It’s your secret weapon for process improvement.

- Suppliers are the originators of your process, the ones providing the essential inputs.

- Inputs are the raw materials, data, or resources that kickstart your process.

- Process maps out the steps, the nitty-gritty, in turning those inputs into outputs.

- Outputs are the grand finale, the results of your process.

- Clients are the lucky ones who receive the outputs, benefiting from your streamlined process.

Visual management: Your SIPOC sidekick

Now, let’s talk about the dynamic duo: Visual Management and SIPOC.

Visual Management is like your trusty sidekick, helping you track and communicate the performance of your key processes.

Imagine using a Kanban board to monitor the progress of customer orders or a chart to keep an eye on order processing times.

These visual tools bring process insights to life, helping you pinpoint bottlenecks and measure the impact of your improvement efforts.

Mastering SIPOC in 3D : Cost, Quality, and Delay

Ready to dive deeper? Here’s how to rock SIPOC in the dimensions of cost, quality, and delay:

- Identify the Process: First, choose the process you want to enhance.

- List SIPOC Elements: Break it down with Suppliers, Inputs, Process, Outputs, and Clients.

- KPIs are key: Determine the Key Performance Indicators (KPIs) for each dimension—cost, quality, and delay.

- Gather data: Collect data on your selected KPIs.

- Analyze and improve: Dive into the data to uncover areas ripe for improvement.

- Implement changes: Put those improvements into action.

- Track progress: Keep a vigilant eye on your KPIs over time, ensuring that your changes lead to positive results.

Don’t forget KPIs in your SIPOC

While SIPOC doesn’t explicitly mention KPIs, you can integrate them seamlessly.

Customize your KPI selection to align with your process and business objectives.

Choose measurable metrics that provide a clear picture of progress over time.

Examples of KPIs for Cost, Quality, and Delay

- Cost: Total process cost, cost per unit, cost per defect.

- Quality: Defect count, customer satisfaction, product quality index.

- Delay: Average processing time, on-time delivery rate, cycle time.

Use visual management tools to monitor these KPIs and keep stakeholders in the loop about your improvement journey.

Example: The process of launching a new product

Objective of the SIPOC: Reduce time-to-market and improve product quality.

Suppliers of the Process:

- Product Manager

- Engineering Lead

- Marketing Manager

- Quality Assurance Lead

Inputs:

- New product concept and specifications

- Market research data

- Development resources

- Marketing budget

Process:

- Idea Generation

- Engage cross-functional teams, including R&D, Marketing, and Sales, in regular brainstorming sessions.

- Collect input from customer feedback channels and market trends.

- Concept Validation

- Create a product concept document with features, benefits, and target market.

- Conduct market research, including surveys and focus groups.

- Assess technical feasibility.

- Project Kickoff

- Assign a dedicated cross-functional team with clear roles and responsibilities.

- Develop a project timeline and budget.

- Set measurable goals and success criteria.

- Product Development

- R&D team designs and develops the product according to specifications.

- Implement continuous integration and continuous deployment (CI/CD) for efficient development and testing.

- Quality Assurance

- QA team conducts comprehensive testing, including functional, performance, and security testing.

- Continuously monitor and address issues through bug tracking systems.

- Marketing Strategy

- Marketing team creates a comprehensive marketing plan, including branding, messaging, and launch events.

- Develop marketing collateral and materials.

- Sales Enablement

- Sales team is trained on the product’s features, benefits, and value proposition.

- Create sales materials, such as product sheets and demos.

- Regulatory Compliance

- Ensure the product complies with all relevant regulations and standards.

- Obtain necessary certifications.

- Product Launch

- Coordinate a launch event or campaign to generate excitement.

- Release the product to the market.

- Monitoring and Feedback

- Continuously monitor product performance and customer feedback.

- Make necessary updates and improvements based on real-world usage.

Outputs:

- Successfully launched product.

- Marketing materials and campaigns.

- Sales team trained and ready.

- Continuous product monitoring and improvement.

Clients:

- Customers eagerly awaiting and purchasing the new product.

- Internal stakeholders looking for a successful product launch.

This complex SIPOC involves multiple teams, intricate processes, and several stages, making it suitable for a more comprehensive analysis and improvement effort.

“SIPOC is not just an acronym; it’s a compass guiding businesses towards process excellence.”

In the fast-paced world of business, where small and medium-sized enterprises (SMEs) are constantly striving to stay competitive, we’ve explored a dynamic duo: SIPOC and Visual Management. They offer a lifeline for those seeking to navigate the treacherous waters of continuous improvement.

While Lean has its merits, it’s not always the right fit for resource-constrained SMEs. SIPOC, on the other hand, emerges as the pragmatic alternative—a simpler, more flexible approach that allows teams from various departments to rally behind process enhancement.

Streamline your processes, drive efficiency, and deliver superior results. The journey might be tough, but the rewards are nothing short of transformational.

In summary ; SIPOC : Simplifying SME process excellence

Small and medium-sized enterprises (SMEs) often grapple with the quest for continuous improvement. While Lean methodology is popular for its promise of efficiency, its complexity can overwhelm SMEs, consuming valuable time with uncertain outcomes.

Enter SIPOC—a simpler, more adaptable alternative that’s gaining momentum. SMEs, known for their resource constraints, find in SIPOC a pragmatic solution.

Why SIPOC Over Lean?

Lean excels in process optimization but isn’t universally suited for SMEs. SIPOC, however, offers flexibility, inviting participation from diverse departments.

SIPOC: A Dynamic Tool

SIPOC—Suppliers, Inputs, Process, Outputs, and Clients—enhances processes:

- Suppliers: Initiate the process by providing inputs.

- Inputs: Kickstart the process with raw materials or data.

- Process: Details the steps in transforming inputs into outputs.

- Outputs: Represent the ultimate results.

- Clients: Beneficiaries who receive the refined outputs.

Visual Management: SIPOC’s Companion

Visual Management complements SIPOC, making process data actionable, amplifying the impact of improvement efforts.

Mastering SIPOC: Cost, Quality, and Delay

Unleash SIPOC’s potential by focusing on cost, quality, and delay:

- Identify the Process: Select the process to enhance.

- List SIPOC Elements: Break it down into Suppliers, Inputs, Process, Outputs, and Clients.

- KPIs Are Crucial: Define Key Performance Indicators (KPIs) for each dimension—cost, quality, delay.

- Gather Data: Collect data on selected KPIs.

- Analyze and Improve: Delve into data to identify areas for enhancement.

- Implement Changes: Put improvements into action.

- Track Progress: Vigilantly monitor KPIs over time.

KPI Integration with SIPOC

Though SIPOC doesn’t mention KPIs, seamlessly integrate them to align with your objectives, selecting metrics providing a clear view of progress.

“Six Sigma is a business strategy that enables companies to drastically improve their bottom line by designing and monitoring everyday business activities in ways that minimize waste and resources while increasing customer satisfaction.”

Jack Welch

References :